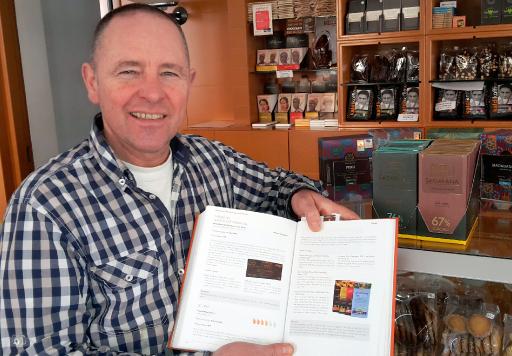

The Art of Chocolate. From the Finest Cocoa to Exquisite Chocolate. part 5

Published by Max Felchlin AG, Schwyz, on the occasion of the 100th anniversary. (2008)

Since visiting Felchlin 2010 and2011, I must admit Im addicted to there chocolate and there philosophy. This book is to interesting not to blog, so I must share this on my blog.

The Bean From Harvesting to Shipping

The picked, ripe an healthy cocoa fruits are cut open. The beans are removed and transferred to wooden fermentation boxes that are not exposed to direct sunlight. This is the traditional and most authentic fermentation method; other modern methods, tailored to large-volume fermentation, are not as natural.

Fermentation Before fermentation, the beans are first inspevted and any rotten or mildewed beans discarded. Fermentation starts a maturation process, which involves microorganisms initiation the fermentation of sugar in the pulp, thus generation heat. The fermentation process kills the seedlings in the beans and relaeses an intense odour and juice runs out of the box. With wine, fermentation ends with cooling, however, with cocoa beans, it ends with drying. Experience gained over the centuries, as well as more recent experiments, have helped to determine the exact point when fermentation is over. Criollo, for example, has to ferment for between two or three days, Nacional for between four to five days and Forastero for between seven to eight days (depending on the hybrid). Experience is also necessary for controlled fermentation in boxes: the beans have to turned regularly to ensure sufficient aeration. Other factors that are key to successful fermentation are air humidity, temperature and the size of the boxes (area, height, width). The type and quality of the wood (soft, hard) also play a role.

Drying After fermentation, the cocoa beans have to be dried with the shrivelled, dry pulp. The best method is a natural one of simply drying the beans in the sun. The fermented beans are spread out in shallow wooden trays or on racks covered with mats made of natural fibres; in the event of sudden rainfall, the mats can simply be rolled up. Drying has to be monotored continuously (almost a daily occurrence in the Tropics), or if the sun is too strong, the beans have to be covered quickly. Three days in the blazing-hot sun is dangerous as the beans are dry on the outside but still moist on the inside; this means that will later sweat, give off moisture and then go mouldy during transportation or in storage. Depending on conditions and variety, drying takes between three to eight days. When shipped, beans should not contain more than 6.5 percent moisture.

FERMENTATION METHODS

Fermentation is a natural, spontaneous process that has a major influence on the quality of the flavour of cocoa. By using suitable infrastructures and methods, its possible to control the process and thus the resulting flavour.

Unfermented : the beans start to ferment spontaneously in the transport containers but with no control whatsoever. They are then taken straight to the drying stage, which means that virtually no fermentation takes place. Quality: poor.

Piles : the beans are collected into piles, covered with banana leaves and then left to ferment spontaneously. No infrastructure is required; the process is difficult to control. Quality: moderate to good.

Sacks or baskets : the beans are left to ferment in transport sacks or baskets. Simple infrastructure; only suitable for small quantities. Quality: moderate to good.

Boxes : the beans ferment in wooden boxes and are periodically turned, aerated and checked. Good control; relatively expensive infratructure. Quality: good to very good.

Selection Buyers differentiate between different qualities of cocoa beans. Thes differences are nothing to do with the actual variety, rather they are the result of the preceding stages, from cultivation to drying. The qualities selected have different names, depending on the country of origin.

For example, in the Dominican Republic, the highest quality is Hispaniola; the buyer has a say in processing and can, for instance, have any beans that are too large or too small removed to ensure uniform roasting sesults: beans that are too small quickly burn and those are too large are not roasted all the way through. In the Dominican Republic, the poorer quality bean is known as Sanchez. Local selection is important as this is the only way to determine the quality. Although the flavour can be influenced at a later stage (roasting, conching), the basic quality cannot (bean variety and size, fermentation, drying).

Most chocolate producers buy cocoa from traders in Europe, for example, in Geneva or Amsterdam. However, Felchlin does things differently. The specialists from Schwyz travel to the place of cultivation, taking the long journey and sometimes arduous communication in their stride in order to buy the cocoa beans at source. This enables them to use their expertise, to astablish relationships abd exert a direct influence on the properties of the beans. This personal commitment has a positive effect on qulity and any variations are relatively easy to prevent.

DRYING METHODS

The fermented beans still contain approx. 60 percent water. This has to be reduced to less than seven percent so that the beans can be tranported and stored. Slow, careful drying is important for the resulting quality and can take up to seven days.

Sun-drying The beans are spread out to bamboo mats or wooden tables and, depending on weather conditions, protected from strong heat or heavy rains. Its easy to turn and move the beans and the condition of the beans and the drying process can closely monitored. However, a large amount of manpower is needed and the long drying time is weather-dependent. Quality: good to very good.

Artificial heat The beans are heated in long, deep trays by bloxwing air that has been heated artificially through a perforated base. There are also other systems for transferring heat. Large quantities can be dried quickly, even in poor weather conditions. However, drying is uneven, often forced and, in the worst-case scenario, the beans can be contaminated with smoke from the combustion facilities. Quality poor to satisfactory.

Next time: The Journey From the Farmer to Basel